Saving Lives with Prototyping

Medical device prototyping for manufacturing is an incredibly beneficial process that can help streamline the development of medical devices. It allows manufacturers to test and refine their designs before committing to mass production, ensuring that the final product meets the highest quality standards. By utilizing prototyping, manufacturers can save time and money while ensuring that their medical devices are safe and effective for their intended use. It is an invaluable tool for medical device manufacturers.

Safety

If you research statistics for medical device recalls and and the injuries attached to them, you may find the results to be eye opening. This concern points to a lack of proper regulation and oversight when it comes to the production and distribution of medical devices, which can have serious consequences for those using them. As a result, it is essential that the medical device industry is held to a higher standard to ensure that these products are safe and effective, and that any issues are addressed quickly and efficiently.

Medical device prototyping in manufacturing is a great way to ensure the safety of device users. By creating prototypes of the device, manufacturers can test and analyze the product to ensure it meets safety standards. This helps to identify any potential issues before the device is released to the public, which can help to reduce the risk of injury or harm. Additionally, prototyping can be used to test the usability of the device, ensuring that it is easy to use and understand. By taking the time to properly prototype and test devices, manufacturers can help to ensure the personal safety of their device users.

Savings

Medical manufacturers that prototype their products can create significant savings through identifying design flaws and improving production methods. By prototyping, manufacturers can identify make the necessary changes to the product before it goes into full production. This can save time and money, as any flaws that are discovered during the production process can be costly to fix.

Furthermore, prototyping can help manufacturers to identify the most efficient production methods. By testing different production methods and materials, manufacturers can determine which methods are the most cost-effective and efficient. This can help to reduce production costs and improve the quality of the final product. Additionally, prototyping can help manufacturers to identify potential problems that may not have been anticipated before production. This can help to reduce the risk of costly delays and mistakes during the production process. Medical manufacturers that prototype their products can create significant savings by identifying design flaws and improving production methods.

Compliance Procedures

Rapid prototyping can be a great asset to manufacturers of medical devices to improve their compliance procedures. This technology allows manufacturers to quickly and accurately create 3D models of their products, which can then be used to test for compliance with various standards and regulations. By utilizing rapid prototyping, manufacturers can save time and money in the development process, as well as reduce the risk of non-compliance. Rapid prototyping also allows manufacturers to quickly create prototypes for testing and feedback, which can help to ensure that the final product is compliant with all applicable standards and regulations. In short, rapid prototyping can be a valuable tool for manufacturers of medical devices to help ensure that their products meet all necessary compliance requirements that are in place for various safety and other important purposes.

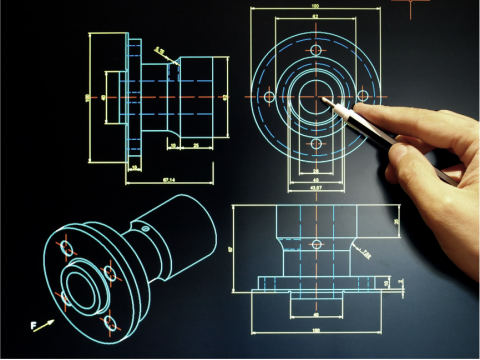

Medical manufacturers have the ability to prototype products and continually make improvements to their devices. Through the use of 3D printing, medical manufacturers can rapidly create prototypes and test them in a cost-effective and efficient manner. Additionally, medical manufacturers can use Computer-Aided Design (CAD) to create detailed models of their products, which can be used to make improvements and modifications to the design. By utilizing these methods, medical manufacturers can prototype products and make endless improvements to their devices in order to provide the best possible solutions for their customers.

Saving Lives

Medical equipment manufacturers that integrate prototyping into their design process are taking a crucial step forward in creating better medical equipment that can save more lives. By taking the time to prototype and test their designs, manufacturers are able to identify any flaws or issues before the equipment is released to the public. This allows for the development of more reliable and effective medical equipment that can be used to help countless individuals. By utilizing prototyping, manufacturers can ensure that their medical equipment is of the highest quality and is able to provide the best possible care to those who need it.

Source: Medical Product Outsourcing