PLA Recycling

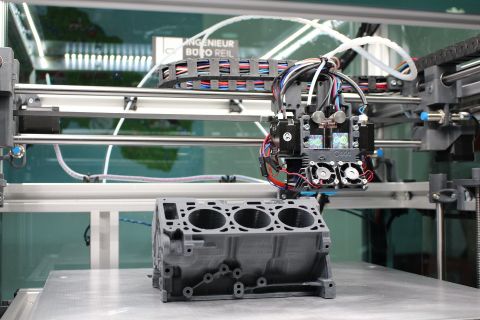

Design Department utilizes a variety of methods to generate prototypes and product samples. A reliable process for the production of full prototypes or components that go into the development of a sample product is 3D printing. While this is a vital tool in prototype development, it is also vital to utilize proper plastic materials and follow environmentally approved recycling techniques for any generated waste.

Due to the focus on reducing plastic waste, it is important to find ways to minimize the impact it has on the environment. To that end, the question must be asked if the materials used in 3D printing processes can be recycled. These materials include Thermoplastics, Polylactic Acid (PLA), and the process of Fused Deposition Modeling (FDM).

PLA is a widely used filament as it has excellent printability, good accuracy in dimensions, and low cost. Due to it being a plant starch based polymer, it is a more eco-friendly choice compared to petroleum-based ABS filaments. Another recyclable option are FDM filaments. FDM filaments use thermoplastics, plastics which can be melted, shaped, and re-solidified when they cool, which are layered to form a 3D object.

There are a variety of other ways to reduce plastic waste in the 3D printing process. These include proper bed adhesion, performing regular printer maintenance, minimizing support materials, and opting for the use of recycled materials. Investing in special equipment, such as a filament extruder and recycling in-house materials also help the environment and reduce cost. Design Department strives to adhere to the most effective plastic usage and recycling techniques in all projects.

For a more in-depth examination of recycling 3D printing materials, you can read this article.